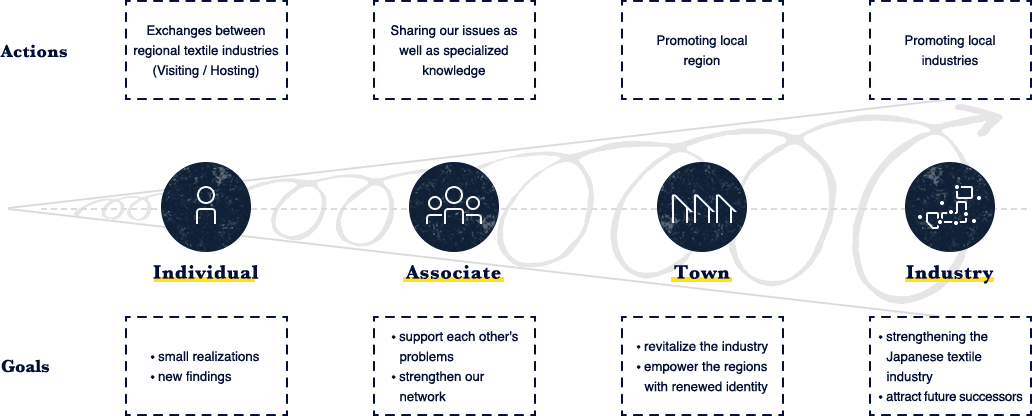

Project

Ok, so let's talk seriously

about textiles!

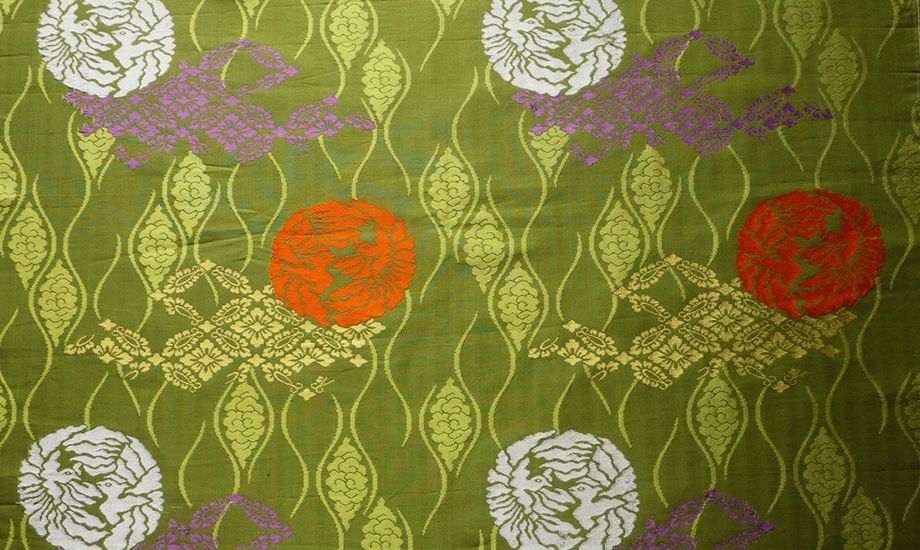

which is situated in the northern part of Kyoto Prefecture in Japan.

Its textile industry dates back as far as the Nara Period (710–784),

with a famous tango chirimen crepe silk culture that boast a 300-year history.

But the town’s pride and joy —its textile industry—has been losing

its foothold in recent years.

This can be said for many of Japan’s industries,

which is why we shouldn’t take it for granted that these

precious traditions will live on into the future on their own.

We want to share with you our concerns, troubles and joys

from our experiments and trials .

We want to talk openly about what we can do

for the textile industry moving forward.

This is why Yosano’s young textile weavers are

visiting production areas throughout Japan…to share

our trials and tribulations and for the future of our local industries.

If we make up for each other’s shortcomings and combine our strengths,

we may be able to create new opportunities and add new value to the textile industry.

Let’s give it a go, together!

View Details

Agenda

Agenda

What we are looking for…

What we can offer…

1. People

2. Production

3. Origins

4. Distribution

5. Technology and the times

6. Community ties

7. Successors

8. Materials

9. Moving forward

10. Local products

View Details

The Weavers

-

Seiya KOIKE

Seiya KOIKE

Seiya KOIKE

KOIKE TEXTILES

I’m the 4th generation of Koike weavers. I spent six years at a well-established textile company in Kyoto City, before I decided to bring back what I learned to Yosano to explore new possibilities.

-

Nobuhiko HAGA

Nobuhiko HAGA

I am really keen to talk with young weavers in other production areas to discuss how they are dealing with successor issues and to talk about their looms and local production areas, as well as how we can create opportunities to showcase the works of the next generation of young weavers.Nobuhiko HAGA

HAGA TEXTILES

I’m a 3rd generation Haga weaver. We produce jacquard silk weaves for products such as kimonos, undergarments for kimono, and dyed obi ties. In 2014, I was certified by the Kyoto Prefectural Government as a Kyoto Certified Craftsman. -

Miho HARADA

Miho HARADA

For textile producing areas, I think there are opportunities in offering small lot orders and made-to-order requests. I wonder how developed other areas are. I think Yosano has a great deal of potential.

Miho HARADA

PARANOMAD Director/Designer

I moved to this town in June 2015 as part of a movement to revive the region. At the same time, I launched my interior textile design business. I participate in one of the community activities at the textile skills training center, and I am undergoing training for everything from business organization development to design techniques.

-

Shinichi IMAI

Shinichi IMAI

I bet if we tried we could have buyers all over the world. There’s no limit to what we can do. For warp weave, we can weave with 3 or 4 warp threads, thick or thin… you name it! No matter what the order, if it fits through the reed, we can do it!

Shinichi IMAI

Imai Warping Factory

Imai Warping Factory was established 50 years ago. We started out as a weaving warp factory specializing in white textiles, but with the changing times we now cater to a whole range of bespoke warp weave orders. I hope that through this initiative, we can work together to pass on the craft as well as try out new techniques.

-

Masateru WATANABE

Masateru WATANABE

I want to get together over dinner and really talk! I think that building relationships is where it starts. Of course, I hope that everyone will come and visit us here in Yosano and I want to talk about so many things together.

Masateru WATANABE

Watamasa Co., Ltd.

I was born in 1980 as the first-born son of Masatoshi WATANABE, the third generation of Watanabe weavers and Tango chirimen silk weaver. After undergoing training in Kyoto’s Muromachi, I returned to Tango at the age of 26 and began working at Watamasa Co., Ltd. I hope to develop products that leverage our strengths, as well as broaden our sales channels.

-

Naoki YURI

Naoki YURI

I get so excited when someone asks for a certain type of woven product. I’ll try anything if I think it will work and if I think it will work, it usually does. This is the type of spirit that will help Tango survive as a production area.

Naoki YURI

Yuri Machinery Works

I’m the 2nd generation for Yuri Machinery. We mainly produce necktie fabric. We carry jacquard silk. We use a whole range of threads as weft and warp threads. I want to further explore the possibilities of textiles.

-

Toru TAKAOKA

Toru TAKAOKA

I wonder how recently established machinery workshops in other production areas will continue to grow. I would like to know how others see me and view our production area.

Toru TAKAOKA

Takami Machinery Works

I’m the third generation of craftsman for Takami Machinery Works. I was certified by the Kyoto Prefectural Government as a Kyoto Certified Craftsman. We produce white textiles for creating Japanese-style accessories such as furoshiki wraps, kimono neck-pieces and obi ties.

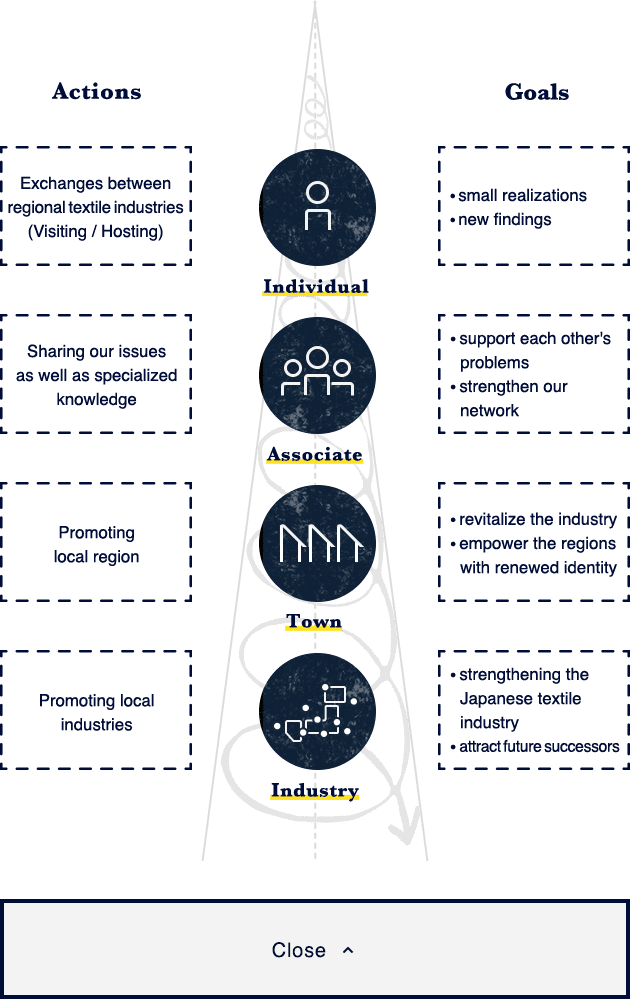

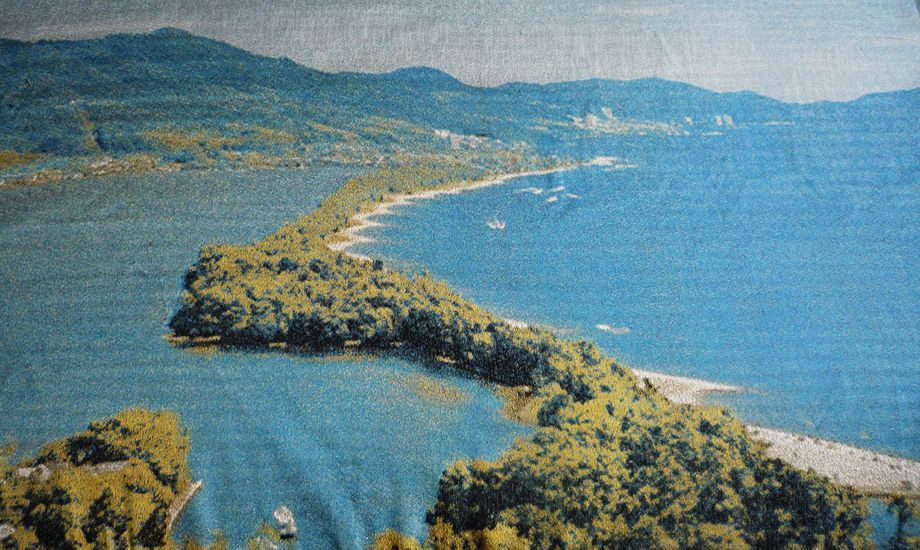

Yosano Town

Tango chirimen has been around for some 300 years. Our predecessors brought back the techniques of the trade from Kyoto Nishijin, and promptly passed it on throughout the region, where it spread rapidly as the local industry. Some say that the silk textile industry blossomed due to the local landscape with its high rainfall and humidity being suitable to silk production, as well as it being a melting pot between Yamato and Izumo culture.

Climate, culture, people. Tango’s textile industry has developed thanks to a variety of factors with production peaking in the mid-1960’s to mid-1970’s. However, currently production volume has fallen to 1/30 of previous peak levels. Amidst this, in recent years we are starting to see a significant shift in craftsmen’s consciousness, so as a production area, we are trying to forge new paths.

From Tokyo

By Train

From Kyoto Station take the JR Sanin Main Line, Kyoto Tango Railway to Yosano (Approx. 2 hrs 20 mins)

From Keihanshin

By Train

(JR Sanin Main Line)

At Fukuchiyama Station take the Kyoto Tango Railway to Yosano (Approx. 2 hrs 20 mins)

From Osaka Station

(JR Sanin Main Line)

At Fukuchiyama Station take the Kyoto Tango Railway to Yosano (Approx. 2 hrs 30 mins)

By Car

Take the Kyoto-Jukan Expressway from Kutsukake Interchange (IC) and exit at Yosano Amanohashidate (Approx. 1 hr 20 mins)

From inner-city Osaka

Take the Chugoku Expressway from Suita Interchange (IC) and exit at Yosano Amanohashidate (Approx. 1 hr 50 mins)

Contact Us

If you have any inquiries, please feel free to contact us.

If you would like to go on a tour of Yosano, Please get in contact with us at the Yosano Commerce and Tourism Division

TEL: 0772-43-9012

shokoshinko@town.yosano.lg.jp

Yosano Commerce and

Tourism Division

We hope to see you soon!

TEL : 0772-43-9012

I get all my missing parts made at the local ironworks workshop. I guess an issue that will arise for us as we move forward is how we maintain our looms and equipment. That’s a challenge for us, but overall, I totally recommend this line of work.